As a decision maker, you know that every decision you make for your business requires a thoughtful consideration of the costs and benefits involved. Here we will show that not only is a retrofit eco-friendly, safe, and cost effective in the long term, it is a great way to present a bright, clean, and contemporary look to everyone who enters your space.

Retrofitting will Save You Money

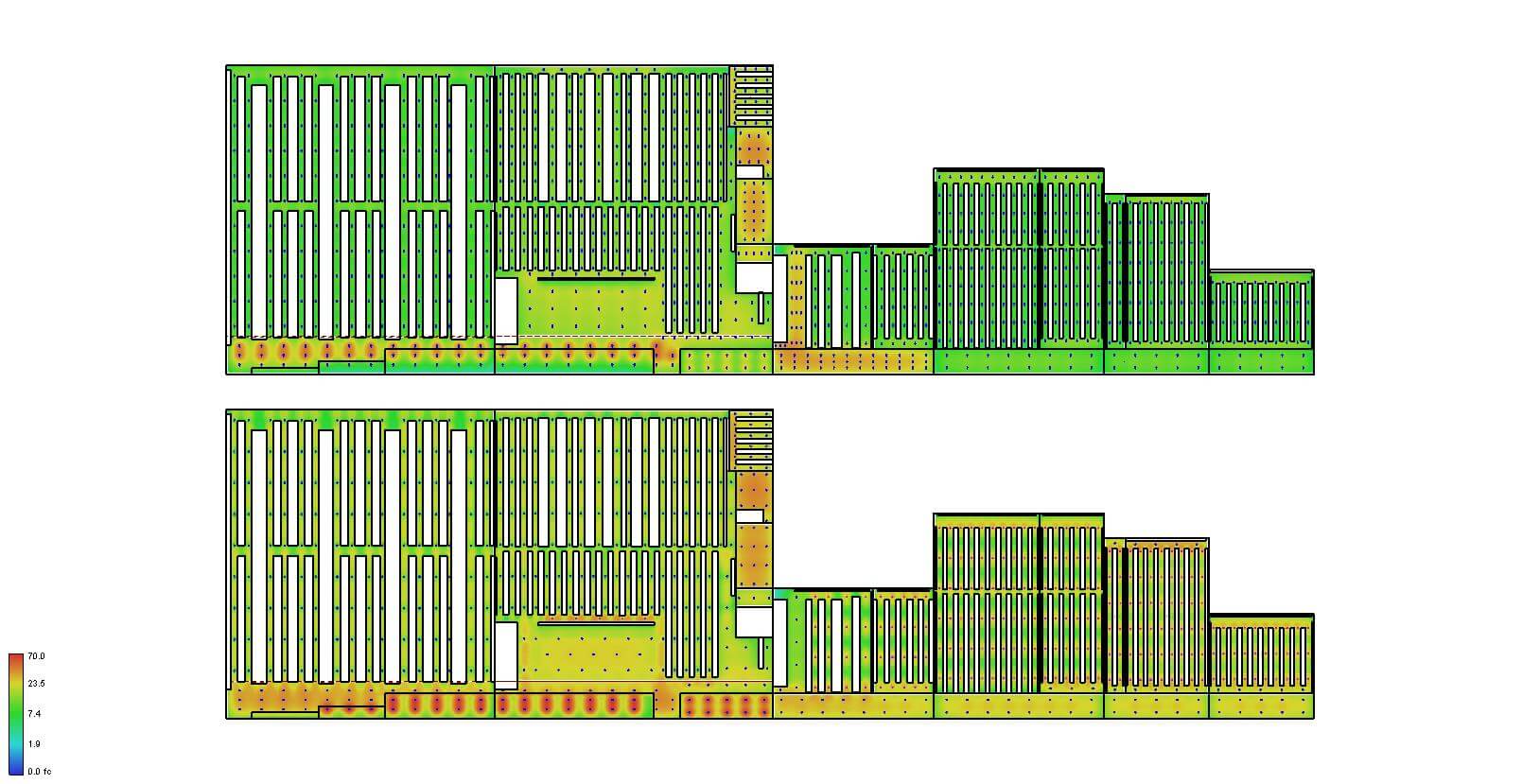

While the upfront cost of a retrofit may seem overwhelming, in the long term you will keep more of the profits you make because your overhead (lighting) will cost less. A cost benefit analysis of switching from fluorescent lighting to LED was done at Southwestern Oklahoma State University. They found that switching to LED would save them over $930,000 cumulatively over the course of 10 years. The analysis shows that the savings in energy costs far outweighs the higher expense of the fixtures themselves. They also note that because LED generates far less heat, during warmer months and in warmer climates the cost of cooling is lowered.

Retrofitting Makes Your Space Safer

LED is solid state, which means there are no harmful gases to worry about. And because they are constructed from plastic, they won’t shatter into sharp shards of glass. And as previously stated they produce very little heat, so handling them after use will not burn bare skin. In addition, the light produced by LED is easier on the eyes and creates less lighting fatigue than fluorescent lights. As noted in the SWOSU analysis, this is due to their low emission of infrared light and zero emission of ultraviolet light. All this adds up to a safer environment for your employees and customers.

Retrofitting is Better for the Environment

Less electricity used means less fossil fuels burned which means less carbon emissions. We all want to lower our carbon footprint and slow the rate of global climate change. While retrofitting your lighting may not be the most drastic green action you can make, it is among the lowest cost-of-entry steps you can take into a more carbon-neutral footprint.

Modern Fixtures for a Modern World

LEDs are bright, rich in color variety and send a message that your business is forward-thinking and environmentally conscious. When someone steps into your space, they should feel welcomed and safe. Bright, warm lighting is an excellent way to make your business more inviting. Cooler lights show a product’s true colors when on display. There are attractive solutions available for every need and purpose your business has. And a well lit space makes people feel safer; they can see who they are with, what they are doing, and where they are more clearly.

In short, LED lighting technology is an easy win for everyone.

For more information on how to retrofit the lighting in your business contact us.