Technological advances in the 21st century can be summarized by several key words; innovative, avant-garde and prolific to highlight a few. However, in a world where energy resources, the growing population and the increasing demand for available energy are all in direct competition, perhaps no technological goal should be more pressing than the creation of efficient energy.

Technological advances in the 21st century can be summarized by several key words; innovative, avant-garde and prolific to highlight a few. However, in a world where energy resources, the growing population and the increasing demand for available energy are all in direct competition, perhaps no technological goal should be more pressing than the creation of efficient energy.

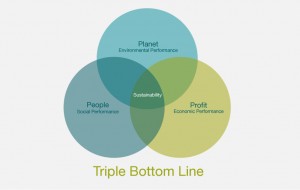

Efficient energy use strives to reduce the amount of energy required to accomplish such tasks as interior and exterior lighting, home insulation and transportation through the creation of products that simultaneously use less energy and last longer. The goal is to create energy that is as self-sustaining and re-usable as possible without compromising the quality of the product.

Our modern world runs on batteries, electric lights and staff willing to work late nights in front of glowing computer screens. In a corporate, technologically-advanced society like the one we live in, efficient lighting surfaces as one of the key ways that everyone from the head CEO to the stay-at-home mom can participate in energy conservation. The benefits of simple modifications that increase lighting efficiency in homes and offices are reflected on both the electric bill and in the long-term health of the planet and longevity of its resources.

Use of LED lighting has long been recognized as a front-runner in energy efficiency. LEDs are simple to install. They’re affordable, long-lasting and provide energy-efficient technology that makes an immediate (and significant difference) in the production of sustainable technology.

The future of LED lighting is even brighter thanks to a ground-breaking new study out of Europe called the NEWLED Project. The study is based out of Scotland and will run through 2016. It aims to “develop a new generation of 50-60% energy efficient white light-emitting LED lights, which would be more than twice as efficient as existing LED-based bulbs”. Those involved with this European-wide project believe that “the higher efficiency white-light LEDs, if widely implemented, could have a significant effect on reducing global energy consumption and CO2 emissions”.

The study holds that these light bulbs “will enable effective heat dissipation and light management and the devices are expected to have applications in automotive, industrial lighting and displays. Widespread use would cut global energy consumption by about 10%”.

Advances in LED lighting, like the ones heralded by the NEWLED project, will continue to increase the availability of green, energy-efficient technology. As consumers it is both our responsibility and privilege to use the resources that both meet our energy needs and conserve the earth’s resources.

For more information please contact us.

If your business operates with cold-storage facilities, you know the importance of maintaining an absolute temperature; however, did you know lighting can be a source of generated heat? This extra energy can cost you more money than you may realize.

If your business operates with cold-storage facilities, you know the importance of maintaining an absolute temperature; however, did you know lighting can be a source of generated heat? This extra energy can cost you more money than you may realize.

It has been estimated that only about 10% of eligible companies have taken advantage of the Commercial Building Deduction known as EPAct, originally implemented in the Energy Policy Act of 2005. Are you among them? If not, you still have time, but you’ll need to act quickly. The “go green” incentive is set to expire at the end of 2013.

It has been estimated that only about 10% of eligible companies have taken advantage of the Commercial Building Deduction known as EPAct, originally implemented in the Energy Policy Act of 2005. Are you among them? If not, you still have time, but you’ll need to act quickly. The “go green” incentive is set to expire at the end of 2013.

Walmart is striving to be a leader in energy reduction. In the early 1990s, it built two experimental stores to test energy saving techniques. One store was located in CO, and one in TX. In 2006, it retrofitted the TX store to try several new energy saving techniques.

Walmart is striving to be a leader in energy reduction. In the early 1990s, it built two experimental stores to test energy saving techniques. One store was located in CO, and one in TX. In 2006, it retrofitted the TX store to try several new energy saving techniques.

Relumination is proud to announce the completion of the

Relumination is proud to announce the completion of the

Most food service businesses have cold storage facilities and if your business fits into that category, we strongly urge you to consider upgrading your lighting system. Lighting efficiency is a major concern especially in areas where the lights, themselves, work against keeping the area cold. Energy efficiency, money, the environment, and a safer, more efficient system all argue in favor of upgrading outdated lighting systems in favor of newer technology that allows an area to be well-lit while keeping the room cold.

Most food service businesses have cold storage facilities and if your business fits into that category, we strongly urge you to consider upgrading your lighting system. Lighting efficiency is a major concern especially in areas where the lights, themselves, work against keeping the area cold. Energy efficiency, money, the environment, and a safer, more efficient system all argue in favor of upgrading outdated lighting systems in favor of newer technology that allows an area to be well-lit while keeping the room cold.

The excellent life span of LED Lighting is well-known. They often have five to ten times or more the life span of the lamps that they replace. Now, advances in the use of polycarbonate (PC) resins for covers, lenses, and reflectors stand to further complement the longevity of LEDs. This is particularly true of their use in outdoor applications, where storms, vandalism, etc. can threaten such luminaries.

The excellent life span of LED Lighting is well-known. They often have five to ten times or more the life span of the lamps that they replace. Now, advances in the use of polycarbonate (PC) resins for covers, lenses, and reflectors stand to further complement the longevity of LEDs. This is particularly true of their use in outdoor applications, where storms, vandalism, etc. can threaten such luminaries.