Traditional warehouse lighting is fraught with problems. The older “bell style” High Pressure Sodium and Metal Halide lighting is terribly inefficient, costly to maintain and emits a poor quality of light. Many warehouses have switched to linear fluorescent technologies like T8 and T5 lighting only to find out afterwards that any savings in electricity costs has been more than consumed by the additional maintenance related to these systems.

It seems like warehouse owners and operators just can’t win when it comes to lighting. Well that was the past. Facility managers now have a smart choice in lighting – intelligent LED Lighting.

Intelligent LED lighting combines the energy savings of LED’s (40-60% ) with the ability to manage the lighting system through technology such as 0-100% dimming, daylight sensing and occupancy monitoring.

Interstate Warehousing in Indiana, Ohio and Tennessee chose to upgrade to intelligent LED lighting from Digital Lumens’. In the new area of the Indiana facility, the LED system saves $30,000 per year in comparison to the older area of the warehouse. The secret to the cost savings in the Digital Lumens system is that the lighting can be programmed to conform to the warehouse usage, and can be set to dim or shut a light off in an aisle or area during periods of inactivity. Refrigerated warehouses will see even more savings because LED lighting gives off no heat, therefore lowering cooling costs!

Similarly, the Cold Canyon Material Recovery Facility reduced its energy costs by two-thirds by replacing more than 80 400-watt metal halide lamps with 148-watt LEDs, saving the company more than $13,000 annually! John Ryan, facilities manager, said the employees love the “brighter, whiter light.” With no maintenance costs and a 50,000-hour lifetime, Cold Canyon will see a return on investment in less than three years.

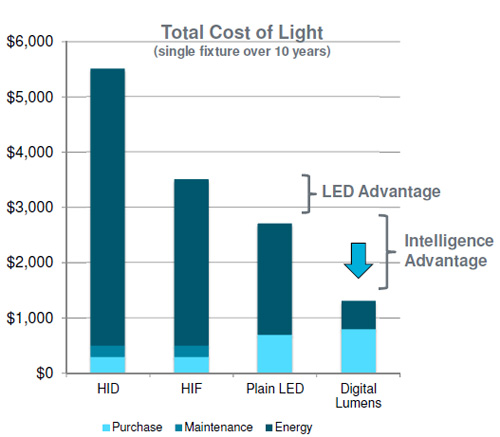

Reducing operating costs is top-priority for warehouse and distribution center owners. Maximizing efficiencies in all aspects of the operation are being used to squeeze as much cost savings as possible. Intelligent LEDs can reduce lighting related operating expenses by as much as 90% and often have a payback under 1 year. Over their lifetime, Intelligent LED Lighting costs 8-10 times less than traditional lighting. That’s money in the bank!