Your facility’s need for a lighting retrofit is clear to you. Yet, your supervisor, the owner, or another leadership team member needs to be convinced it’s time to move forward. Objections to a commercial lighting retrofit frequently are based on misconceptions you can overcome with facts. Here are ways to advocate for your facility’s commercial lighting retrofit in the face of three common objections.

Objection: A lighting retrofit is costly. Our organization has other budget priorities.

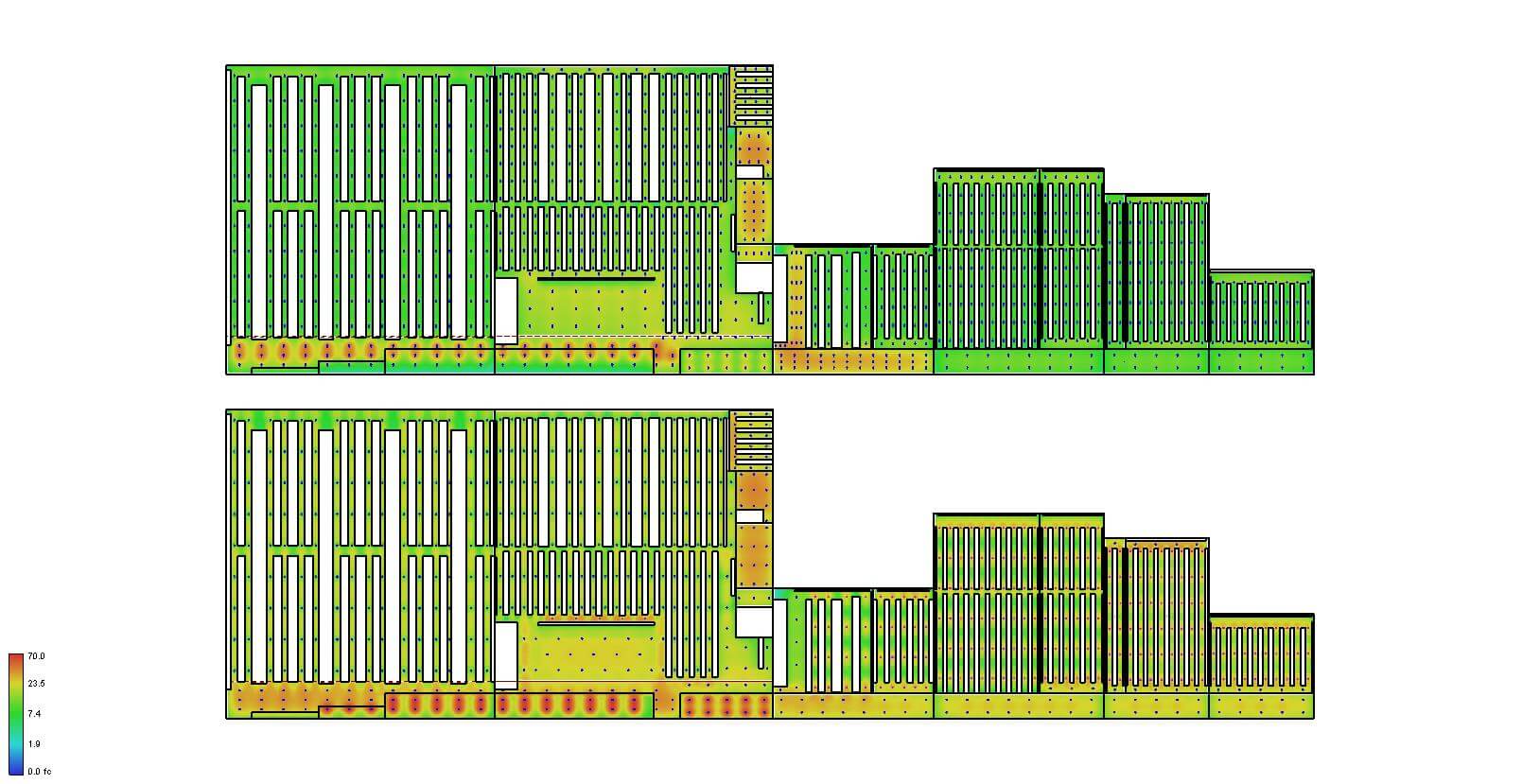

Response: Many organizations realize a return on investment for their lighting retrofit in less than three years. Today’s highly energy-efficient lighting solutions decrease maintenance and energy costs. For example, an Oregon grocery distribution center saved $189,811 in annual energy costs and $47,000 in annual maintenance costs as a result of its lighting retrofit. Experienced lighting solution providers like Relumination offer free lighting consultations to determine the viability of a lighting upgrade.

Also, a lighting retrofit usually qualifies for significant utility company incentives. The professionals at Relumination know how to get the maximum utility rebate their clients are eligible for.

Objection: We did a lighting upgrade 12 years ago. We don’t need a lighting retrofit now.

Response: That upgrade was to T8 fluorescent lighting. Switching to energy-efficient LED lighting would reduce energy costs. Although we did see a measure of energy savings from going to T8 fluorescent lighting back then, a portion of those savings resulted from T8 fluorescent’s lower light levels. By choosing LED lighting, we could simultaneously increase light levels and lower costs.

Objection: There isn’t a business need for a lighting retrofit.

Response: Commercial lighting retrofits have benefits for all of our stakeholders. Since a retrofit can improve light levels, employees make fewer mistakes. In turn, quality control improves and the risk of injury decreases.

In addition, better lighting makes customers feel safer when they come to our facility. For management, the advantages of a commercial lighting retrofit are in the bottom line.

When you overcome your leadership’s objections to a commercial lighting retrofit, contact us at Relumination for a free lighting consultation.